Maintaining an elevator, a crucial aspect of any industrial or construction facility, significantly influences operational costs, safety measures, and environmental performance. At McDonough, we emphasize that diligent maintenance of an elevator is essential not only for the safety and productivity of the workforce but also for the equipment’s longevity. With regular, appropriate care, an elevator can remain operational for up to three decades.

The Crossroads: Reactive vs Preventive Maintenance

Perils of the Reactive or “Run to Failure” Approach

Regularly scheduled maintenance is the secret to maximizing your elevator’s lifespan. Proactive maintenance from the onset of the elevator’s lifecycle is significantly more effective. We’ve often been brought in to assist customers who have allowed their elevators to deteriorate over years of neglect. In such situations, restoring reliability is not only more difficult but also more expensive due to accumulated damage. Some elevators may even be beyond straightforward repair, necessitating substantial upgrades or complete replacements.

Proactive Maintenance Programs

McDonough offers comprehensive preventative maintenance programs focused on ensuring the safe and reliable operation of your elevator. Our programs deliver valuable data to help predict potential component failures, facilitating effective repair planning. With this approach, parts and repairs can be budgeted for, making the process more cost-effective.

Implementing Planned Elevator Maintenance

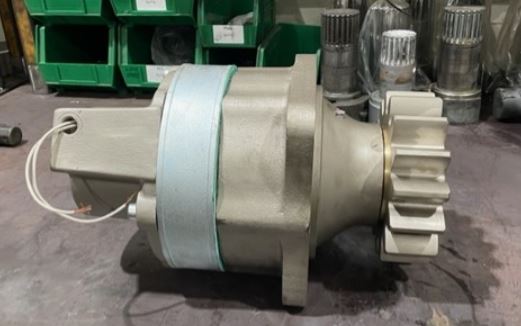

McDonough provides preventive maintenance plans for all brands of rack and pinion elevators. We are committed to making sure the elevators under our care are well-maintained to minimize downtime. Our process is designed to be transparent, enabling our customers to remain informed about their elevator’s current and historical conditions. Together, we can develop the ideal strategy for maintaining your elevators.

For further information, contact us today to schedule a site visit and an elevator consultation. We’re here to ensure your elevators remain in optimal condition, boosting productivity and safety on your site. After all, we are ONE McDonough, and we’re committed to making a difference in your operations.