5 Ways to Improve Reliability of Your Buck Hoist or Construction Elevator

There are a handful of important items that you can control on your jobsite that will improve the reliability of the buck hoist or construction elevator on your next project.

There are a handful of important items that you can control on your jobsite that will improve the reliability of the buck hoist or construction elevator on your next project.

Hoist Operators…should I hire one from McDonough or provide my own? We are often asked if any job site laborer can be trained to operate the hoist and assume all the responsibilities related to the hoist operation. The short answer is yes, but the more

The 2018 hurricane season is here. A total of 14 named storms, 7 hurricanes and 3 major hurricanes are expected this season from June through November according to Colorado State University’s Tropical Meteorology Project. A major hurricane is Category 3 (111-129 mph winds) or stronger. While

More plant safety departments, turnaround managers, and general contractors are requesting temporary personnel/material hoists for use during outages and turnarounds on the taller structures in the plants. Common structures that utilize temporary personnel/material hoists include FCC units, crude and vacuum towers, coker units, furnaces, and

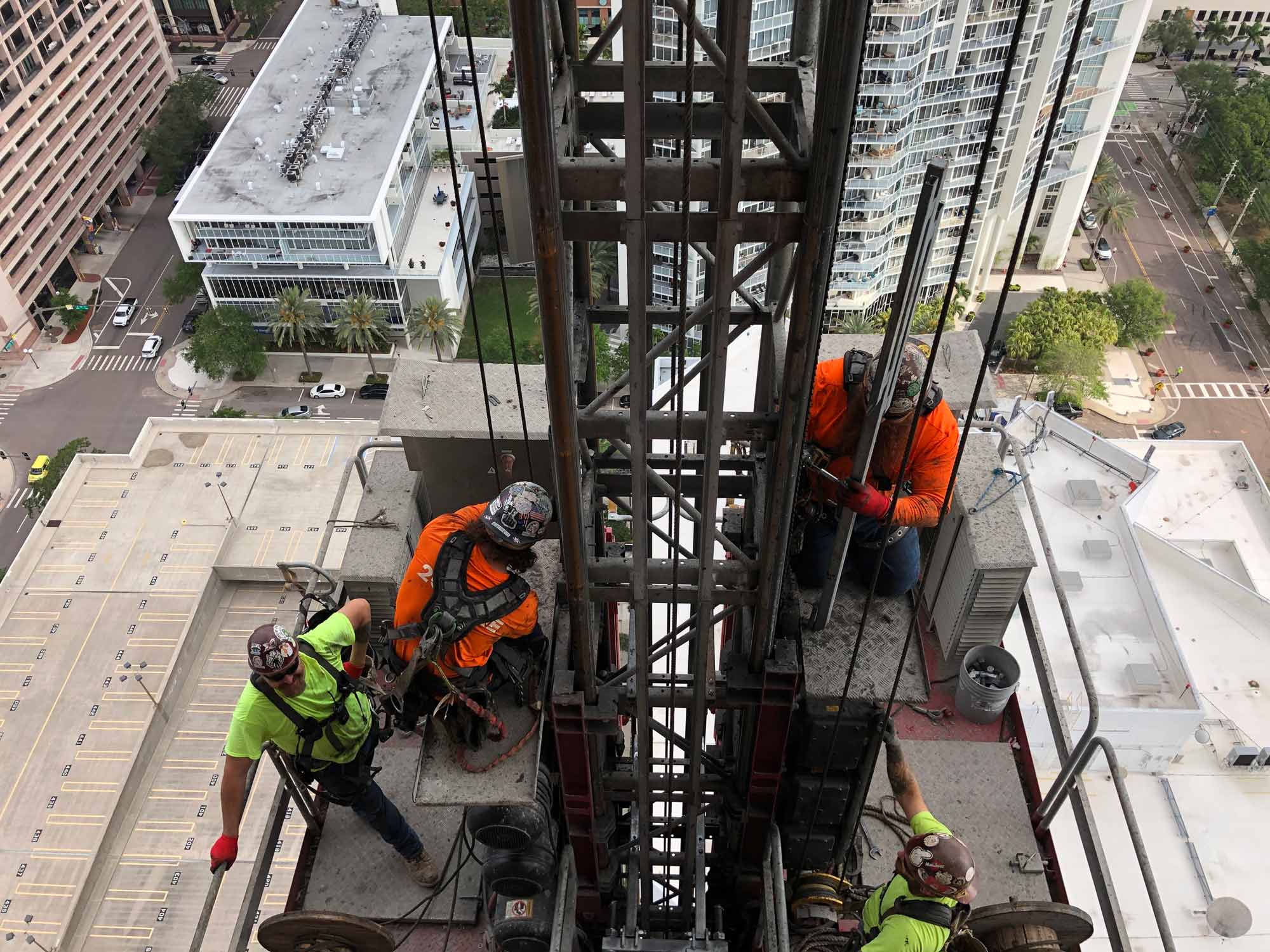

We really admire our crews and others who day after day climb and work far above our heads either installing, dismantling or maintaining rack and pinion elevators. Our elevators are workhorses, employed at an incredible variety of construction, mining, and industrial sites across the country.

If you are having your rack and pinion elevator maintained by the original manufacturer, chances are you will receive Original Equipment Manufacturer (OEM) parts. Just like in other industries (automobile, appliances and others), aftermarket parts exist for elevators. Is there anything wrong with aftermarket parts?

Maintenance can be the largest controllable operating cost for our customers. It is a critical business function that impacts not only plant operations, but also safety and environmental performance. For McDonough Elevators, we believe proper maintenance of an elevator is important for worker productivity, safety and longevity

We like to brag about the strength and durability of our elevators. McDonough Elevators are built to perform in extreme, intense working conditions. What makes them strong enough to stand up to the harshest of environments? The thickness of our car walls and the bracing of

Many times we have been requested to provide the Country of Origin for our elevators. As the term was originally conceived, Country of Origin was supposed to be a single location which encapsulated the brand’s origin, the place of design, and the place of production.